During the exciting Code-a-thon at Caterpillar Inc., our team was thrilled to present CATTY—an innovative AI-powered XR application that transforms the way equipment inspections are performed. Utilizing the cutting-edge Meta Quest 3, CATTY introduces a hands-free, highly accurate inspection process with its advanced LiDAR technology. Ever thought you could inspect equipment without lifting a finger? Well, now it’s possible!

🎯 Elevating Inspection Standards

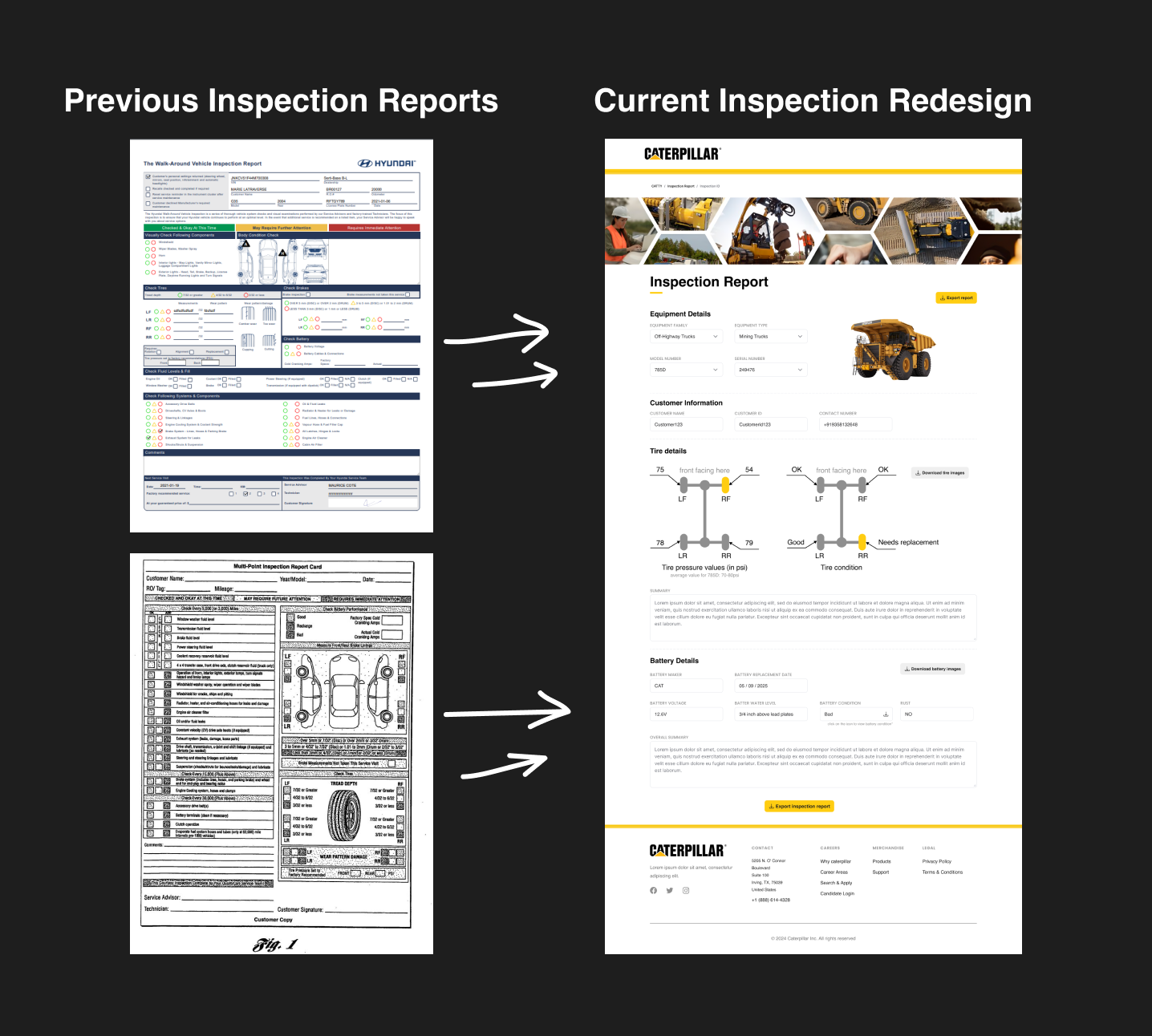

Say goodbye to the old-school clipboard and pencil! Traditional inspection methods can be tedious and error-prone. CATTY leaps into action, blending immersive VR with real-time AI analytics to ensure inspections are both thorough and precise.

Market Need and Innovation

As technology advances, so does the need for more efficient and reliable inspection methods. CATTY addresses this need by combining XR and AI, offering a revolutionary solution that boosts operational efficiency and enhances safety. Imagine having a superhero gadget that makes inspection tasks a breeze!

🧩 How CATTY Works

Easy Start

Kick off inspections with simple voice commands. This hands-free approach lets technicians concentrate fully on the inspection task, without any distractions. Just say the magic words, and you’re all set!

Enhanced Real-Time Analysis

Equipped with the Meta Quest 3’s LiDAR sensor, CATTY can spot issues from minor wear and tear to serious safety concerns. This feature allows for capturing incredibly detailed visual data, enabling precise defect detection—it’s almost like having superhuman vision!

Voice-Activated Reporting

While on the move, inspectors can verbally report their findings. CATTY’s state-of-the-art speech recognition software converts spoken words into written reports effortlessly, simplifying documentation and minimizing manual input.

🎨 Design and User Experience

A key component of CATTY’s success is its intuitive and functional user interface, designed to withstand the rigors of industrial environments. Below is an example of CATTY’s inspection report interface, which exemplifies our commitment to clarity and usability:

🔦 Looking Ahead

We’re not stopping here! Plans for future enhancements include adding more language options and integrating predictive maintenance capabilities. This way, CATTY will not only keep up with the times but actually stay ahead, helping to predict and prevent equipment failures before they even happen.

🚀 Conclusion

CATTY is more than just a tool; it’s revolutionizing inspection practices and setting new benchmarks for maintenance reliability and efficiency. It represents a major leap forward in future-proofing industrial operations. Ready to embrace the future of inspections?

Curious about CATTY or want to share your thoughts? Drop a line!

For an in-depth look at our design journey: Check out the Figma file! 🚀